OSHA Dental & Medical Office

According to OSHA 3187 Medical & Dental Offices, the health industry must adhere to all safety standards prescribed by it which are intended to prevent workers from Bloodborne Pathogens (and Needlestick Safety and Prevention), provide effective hazard communication to workers (Right To Know), Ionizing Radiation, Electrical Safety compliance and standards and emergency Exit Routes arrangements.

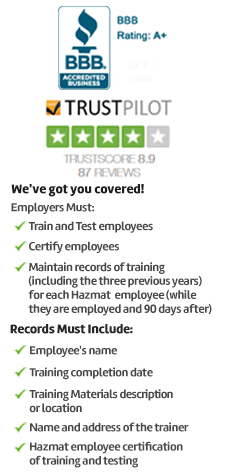

The safety and health standards include training requirements that applicable to dental and medical offices, irrespective of the number of employees. Green World Group has formulated a cost-effective bundle by combining all these five safety courses for the sake of students and working professionals.

Governing regulations

This online course bundle satisfies the training requirements for the following:

OSHA 29 CFR § 1910.1030 Bloodborne Pathogens (and Needlestick Safety and Prevention) Standard;

OSHA 29 CFR § 1910.1200 Hazard Communication Standard (Worker Right To Know);

OSHA 29 CFR § 1910.1096 Ionizing Radiation Standard;

OSHA 29 CFR § 1910 Subpart E OSHA 29 CFR § 1910 Subpart L Exit Routes & Fire Protection Standard;

OSHA 29 CFR § 1910.301 to 1910.399 Electrical Standard;

Course Overview

Our OSHA medical and dental hazard training course is the combination of five courses which satisfy OSHA’s training standards for various hazard prevention mechanisms applicable to medical and dental centres. Each course provides detailed description of applicable safety practices, types of hazards, prevention methods and control measures that can be used to protect workers from various health hazards and risks.

Who Must Take this Course?

People who are directly or indirectly associated with Medical and Dental offices where they can face various health risks and hazards such as electrical, biological, chemical or other toxic substances.

Course Format

Our OSHA Medical and Dental Office Hazards Training course has been bundled in such a way that students get easy to understand content prepared by experts with full of information, graphical analysis, examples, audio explanations and huge bank of questions for self-test for students to clear the final exam with good marks.

Students who are completing the course will get a hard copy of the course completion certificate along with a printable wallet card for their future use.

Continuing education credits?

Each candidate will receive 1.0 CEUs (or 10 CMEs) for completing this OSHA safety training course.

Topics Covered

- Introduction to OSHA’s Bloodborne Pathogens Standard

- Key Terms

- Bloodborne Pathogens Standard

- Needlestick Safety and Prevention Act

- Requirements of the Bloodborne Pathogens Standard

- Bloodborne Pathogens

- Ways Bloodborne Pathogens are Transmitted

- Other Potentially Infectious Materials (OPIM)

- Human Immunodeficiency Virus (HIV)

- Symptoms and Stages of HIV

- Treatment for HIV

- Hepatitis B

- HBV Signs and Symptoms

- HBV Treatment

- Hepatitis C (HCV)

- HCV Treatment

- Occupations with Risk Exposure

- Body Art

- Correctional Department Workers

- First Responders

- Maintenance and Waste Workers

- Employee and Employer Rights and Responsibilities

- Employee Rights and Responsibilities

- Employer Responsibilities

- Training

- Communicating Hazards and Labeling

- Exposure Control Plan

- Elements of an Exposure Control Plan

- Housekeeping

- Sharps Injury Log

- Record Keeping

- Precautions, Controls, and Guidelines

- Universal Precautions

- Engineering and Work Practice Controls

- Needleless Systems and Engineered Sharp Protection

- General Safety Practice Review

- Personal Protective Equipment

- Available PPE

- Laundering PPE per the Bloodborne Pathogens Standard

- Removal of PPE

- Exposure Occurrence

- Procedures for Exposure Incident

- Post-Exposure Evaluation

- Summary

- Introduction to Hazard Communication for General Industry

- Background Information about the Standard

- Major Changes to the Standard

- Importance of the Standard

- Key Terms

- Employer and Employee Responsibilities

- Employee Training

- Chemical Hazards

- Routes of Entry

- Recognition of Health Hazards

- Health Effects of Chemical Hazards

- Chemical Agents and Their Health Effects

- Written Hazard Communication Program

- Additional Requirements of the Written Hazard Communication Program

- Hazard Inventory

- Hazard Classification

- Health Hazard Classes

- Labels

- HMIS and NFPA Labeling Systems

- HMIS Labeling System

- NFPA Labeling System

- Safety Data Sheets

- Exposure Controls: Elimination and Substitution

- Exposure Controls: Engineering and Work Practice Controls

- Exposure Controls: Personal Protective Equipment

- Employee and Employer Rights and Responsibilities

- Employee Rights and Responsibilities

- Employer Responsibilities

- Training

- Communicating Hazards and Labeling

- Exposure Control Plan

- Elements of an Exposure Control Plan

- Housekeeping

- Sharps Injury Log

- Record Keeping

- Precautions, Controls, and Guidelines

- Universal Precautions

- Engineering and Work Practice Controls

- Needleless Systems and Engineered Sharp Protection

- General Safety Practice Review

- Personal Protective Equipment

- Available PPE

- Laundering PPE per the Bloodborne Pathogens Standard

- Removal of PPE

- Emergency Planning and Community Right-to-Know Act (EPCRA)

- Emergency Planning and Emergency Release Notification

- Annual Inventory

- Toxics Release Inventory

- EPCRA Inspections

- Summary

- Introduction to Ionizing Radiation Standard Safety Training

- Regulatory Institutions and Agencies

- Key Terms

- What Is Radiation?

- Ionizing Radiation Versus Non-Ionizing Radiation

- Types of Ionizing Radiation

- Alpha Particles

- Beta Particles

- Neutron Radiation

- Gamma Rays and X-rays

- Ionizing Radiation Exposure

- Sources of Radiation

- Natural Radiation

- Man-made Radiation

- NORM

- TENORM

- Exposure Pathways

- Routes of Internal Exposure

- Chronic Exposure

- Acute Exposure

- Health Effects of Exposure

- Health Effects of Exposure – Cancer

- Health Effects of Exposure – Genetic Mutation

- Safety and Health Programs and Practices

- Employer Responsibilities

- Employee Responsibilities

- Employee Training

- Record Keeping

- Radiation Emergencies

- Caution Signs and Labels

- Caution Signs and Labels – Exceptions

- Immediate Evacuation Warning Signal

- Immediate Evacuation Warning Signal – Design Parameters

- Notification of Incidents

- Summary

- Introduction to OSHA Standard for Exit Routes and Fire Protection

- Key Terms

- Exit Routes and Fire Protection OSHA Standard – History and Background

- Exit Routes and Fire Protection OSHA Standard – Overview

- Applicable Statistics

- Responsibilities

- Responsibilities – Alarm Systems

- Responsibilities – Fire Brigades

- Responsibilities – Personal Protective Equipment (PPE)

- Applicable Regulations for Exit Routes and Fire Protection – Governing Authorities

- Applicable Regulations for Exit Routes OSHA 29 CFR 1910 Subpart E

- Applicable Regulations for Fire Protection OSHA 29 CFR 1910 Subpart L

- Design and Construction Requirements for Exit Routes

- Adequate Exits

- Exit Discharge and Rules for Exit Doors

- Exit Regulations

- Outdoor Exit Routes

- Types of Fire Hazards

- Maintenance, Safeguards, and Operational Features for Exit Routes

- Risk Mitigation and Safe Work Practices for Fires

- Portable Fire Suppression – Fire Extinguishers

- Portable Fire Suppression – Standpipe and Hose Systems

- Fixed Fire Suppression – Automatic Sprinkler Systems

- Fixed Fire Suppression – Fixed Extinguishing Systems

- Fire Detection Systems

- Employee Alarm Systems

- Controls

- Emergency Action Plan

- Fire Prevention Plan

- Training

- Summary

- Introduction to OSHA Electrical Standard Training

- Fatality and Injury Statistics

- Roles and Responsibilities

- Key Terms

- Design Safety Standards for Electrical Systems

- Examination of Equipment

- Installation of Equipment

- Electrical Connections

- Arcing Parts, Markings, and Disconnecting Devices

- Design Safety Standards for Equipment Operating at 600 Volts or Less

- Guarding of Live Parts, 600 Volts or Less

- Design Safety Standards for Equipment Operating at More Than 600 Volts

- Enclosures for Electrical Installations – More Than 600 Volts

- Indoor Installations – More Than 600 Volts

- Space Around Electrical Equipment, More Than 600 Volts

- Working Space, Entrances, and Illumination – More Than 600 Volts

- Wiring Design and Protection

- Branch Circuits and Receptacles

- Testing Equipment Grounding Conductors

- Outlet Devices and Receptacle Outlets

- Outside Conductors, 600 Volts or Less

- Clearances

- Services

- Overcurrent Protection

- Grounding

- Methods of Grounding Fixed Equipment

- Wiring Methods, Components, and Equipment for General Use

- Temporary Wiring

- Cabinets, Boxes, and Fittings

- Switches

- Conductors for General Wiring

- Fixture Wires

- Attachment Plugs and Appliances

- Motors, Motor Circuits, and Controllers

- Transformers and Capacitors

- Specialized Purpose Equipment, Locations, and Systems

- Hazardous Location Classification

- Classifications

- Electrical Installations

- Protection Techniques

- Safety-Related Work Practices

- Work Covered by The OSHA Electrical Standard

- Training

- Content of Training

- General Work Practices

- Work Practices Related to Exposed De-Energized Parts

- Re-Energizing Equipment

- Work Practices Related to Exposed Energized Parts

- Working On or Near Overhead Lines

- Illumination and Work in Confined or Enclosed Spaces

- Conductive Materials, Equipment, and Apparel

- Work Practices Related to the Use of Equipment

- Portable Electrical Equipment

- Electrical Power and Lighting Circuits

- Use of Protective Equipment

- Alerting Techniques

- Summary

- Additional Resources

- Exam

NEBOSH CERTIFICATE

NEBOSH CERTIFICATE NEBOSH DIPLOMA

NEBOSH DIPLOMA IOSH

IOSH SAFETY DIPLOMA

SAFETY DIPLOMA CPD UK

CPD UK ROSPA UK

ROSPA UK FOOD SAFETY

FOOD SAFETY