Safety Procedures Linked to Manual Material Handling at Work Places

Many workplaces do make workers physically handle heavy objects or lift loads of material even though technology has given us several gadgets to handle heavy materials safely under industrial environments.

Even though companies use lifting machines such as cranes to carry heavy loads, there are accidents due to mishandling, inappropriate positioning or faulty equipment. Though it looks simple exercise to move heavy materials manually from one place to another, workers should be experienced, healthy and protected well to perform the daily rigmarole without affecting their health.

Several health issues can be associated with manual material handling by workers which include fatigue, back injury, sprain or twisting, bruises and fracture.

Sometimes mishandling of loads can lead to fatal accidents when workers go under the falling loads or due to improperly staked loads in warehouses, which can be prevented if proper safety procedures are followed.

Safety aspects

Since Manual Material Handling (MMH) can’t be avoided in small and medium enterprises, workers should take adequate care in protecting them from the health implication due to handling heavy loads. There are safety gadgets such as heavy industrial gloves, boots, safety glasses, helmets and attires which are specifically made to protect workers when they move heavy materials either on their own or through shifting equipment.

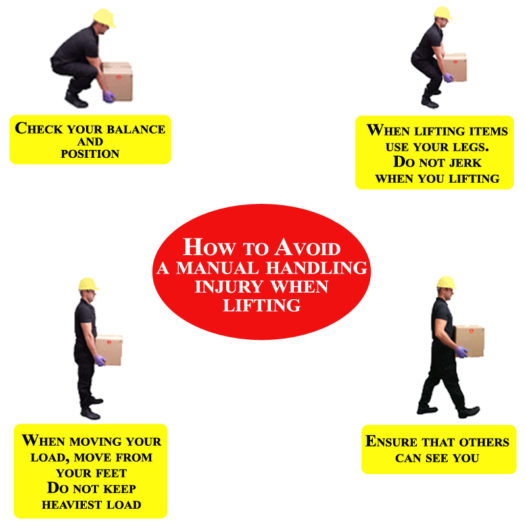

There are certain procedures workers need to follow while loading or unloading heavy boxes. Experienced labourers can guide new ones in lifting techniques which can prevent injuries. Moving the legs apart and bending the knees while lifting heavy items is the universal practice which can prevent workers straining their back. Similarly stacking the heavy loads properly and evenly can prevent accidents such as falling of materials on workers which can sometime be fatal.

Even workers can undergo safety training under the tutelage of HSE professionals which can help workplace managers ensure absolute safety to workers when they are engaged in handling heavy engineering materials. Knowledge on safety equipment’s, lifting machinery and heavy load movers is essential to use them appropriately without compromising on workers’ safety.

Precautions during MMH

When handling heavy goods physically, every load should have proper grip, handle or holder which can be used to lift the items and carry them to the designated places safely. Workplace managers and employers should ensure that their workers wear proper protective gears and use lifting method to prevent unwarranted injury which can lead to absenteeism and extension of work schedule.

Workers should keep the following criteria in mind while handling heavy loads:-

- When a load is heavy, say more than the government stipulated 50 kg, workers should not attempt to lift it alone.

- When the loads lack the mandatory grips and not properly packed.

- When workers are not authorized or experienced to handle a load safely.

- Workers should demand protective equipment or safety wear while manually handling heavy loads. Some of the most frequently used items are heavy industrial gloves, safety eyewear, sturdy shoes or boots, helmet, etc.

As injuries due to mishandling of loads can have long-term ramification on workers’ professional life and also affect the work at site, appropriate safety procedures should be followed for safe manual material handling process.

NEBOSH CERTIFICATE

NEBOSH CERTIFICATE NEBOSH DIPLOMA

NEBOSH DIPLOMA IOSH

IOSH SAFETY DIPLOMA

SAFETY DIPLOMA CPD UK

CPD UK ROSPA UK

ROSPA UK FOOD SAFETY

FOOD SAFETY