Why Does Lifting Safety Deserve More Attention?

Lifting operations are routine in any manufacturing, heavy engineering, and construction industrial worksites. Yet, they’re also one of the leading causes of workplace injuries and fatalities.

In 2023, a crane collapsed at a commercial site in Mumbai due to overloading, leading to two deaths and multiple injuries. It wasn’t the first time. According to a ScienceDirect report, crane instability accounts for over 20 deaths annually in India. Globally, the U.S. Bureau of Labor Statistics (BLS) reports over 40 crane-related fatalities every year.

The reasons for accidents and health disorders due to lifting are many. So, how do we prevent such incidents? The answer lies in planning, training, and treating every lift like a high-stakes operation—because when it goes wrong, there’s no second chance.

What Is Lifting Operation in Safety?

Lifting is the process of moving heavy to very heavy loads either manually by workers or with the help of automated lifting machines. While doing so, lifting technicians, operators, or ground staff can face risks, dangers, and health problems that can lead to loss of employment due to sickness or disability.

Lifting Safety isn’t just about physical strength or advanced machinery —it’s about understanding the risks, using the right equipment, and following a strict set of procedures, because shortcuts in lifting often come with long-term consequences.

Types of Industrial Lifting Machines: Uses, Key Specifications & its Operational Hazards

Choosing the right lifting equipment type is key to safe, smooth, and efficient operations. But each machine has its own limitations and risks. Here’s a quick look at the most used industrial lifting machines—their uses, key specs, and associated hazards.

Hoist

Hoists are compact lifting devices operated manually, electrically, or pneumatically. They are used to lift loads vertically using a chain or rope wound around a drum.

Key Specification: Electric wire rope hoists can typically lift loads ranging from 1 to 20 tons, depending on configuration.

Associated Risk: Failure to inspect chains or ropes can result in dropped loads, entanglement, or equipment malfunction.

Forklift

Forklifts are used for short distance lifting and material handling in warehouses and industrial sites. They operate using electric batteries or internal combustion engines.

Key Specification: Standard forklifts lift between 1 to 5 tons. Advanced models include tilt control systems for load stability.

Associated Risk: Tip-overs and collisions due to poor visibility or improper turning are common causes of injury.

Cranes: Types of Crane Lifting Equipment

Cranes provide both vertical and horizontal movement, making them essential equipment for lifting and transporting heavy materials across construction and industrial sites. Various types of cranes are designed to suit specific tasks, environments, and load requirements.

Tower Cranes

Tower cranes are fixed to the ground and commonly used on high-rise construction sites to lift heavy materials to significant heights. They offer full 360° rotation for versatile load placement.

Key Specification: Tower cranes can reach heights exceeding 250 feet (75+ meters) and lift loads up to 20 tonnes, depending on the load radius.

Associated Risk: Strong winds, improper counterweight balancing, or incorrect rigging can lead to structural failure or collapse.

Telescopic Cranes – Telescopic cranes are the most common types of cranes which have metal tubes fitted with one another and operated using the hydraulic method. With this, an operator can reduce and increase the length of the boom. These cranes can be fitted on moving trucks.

Mobile Cranes

Mobile cranes are mounted on vehicles, allowing quick relocation and flexibility on job sites. They are widely used for lifting and moving loads over short to medium distances.

Key Specification: Mobile cranes typically handle loads ranging from 10 to 100 tonnes, depending on the terrain and crane design.

Associated Risk: Operating on uneven or unstable surfaces, extending the boom beyond safe limits, or overloading can lead to tipping or structural damage.

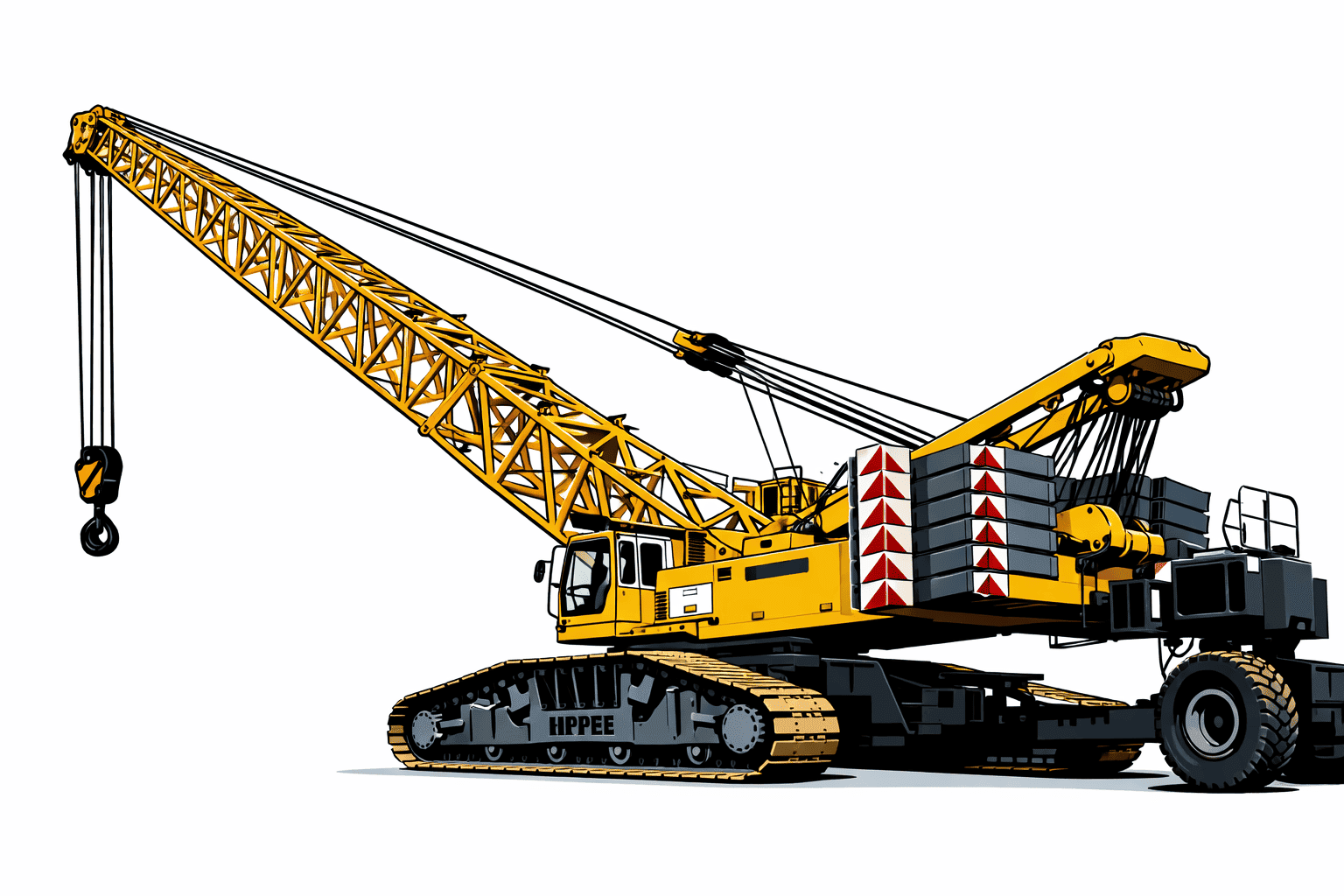

Crawler Cranes

Crawler cranes move on tracks, offering strong stability and easy mobility on soft or uneven ground. Unlike mobile cranes, they don’t need outriggers—making them perfect for heavy lifting in tough site conditions.

Key Specification: Crawler cranes can lift up to 600 tonnes without the need for outriggers.

Associated Risk: Risks include tipping due to unstable ground, mechanical failures, or improper load management.

Other lifting equipment

Power shovels, telescopic handlers, boom lifts, and aerial platforms for lifting both materials and personnel. Each type demands its own set of controls—especially when working at height or in confined spaces.

Lifting safety precautions: Expert-Approved Risk Control Measures

The step-by-step safe lifting procedure are as follows,

Before the Lift:

Assess Ground Conditions – Ensure the surface is level, stable, and suitable for lifting operations.

Assess Ground Conditions – Ensure the surface is level, stable, and suitable for lifting operations. Check the Weather – Postpone the lift during high winds, heavy rain, or poor visibility.

Check the Weather – Postpone the lift during high winds, heavy rain, or poor visibility. Verify Lifting Permits – Ensure all valid permits are in place before starting the job.

Verify Lifting Permits – Ensure all valid permits are in place before starting the job. Inspect Equipment – Examine slings, chains, hooks, brakes, hydraulics, and lifting accessories.

Inspect Equipment – Examine slings, chains, hooks, brakes, hydraulics, and lifting accessories. Install Audible Alarms – Fit cranes or mobile lifting units with reverse horns and visual alert systems.

Install Audible Alarms – Fit cranes or mobile lifting units with reverse horns and visual alert systems. Confirm Load Chart Limits – Always refer to the crane or equipment load chart to prevent overloading.

Confirm Load Chart Limits – Always refer to the crane or equipment load chart to prevent overloading. Ensure Competency & Training – Only certified operators and trained riggers should be assigned to lifting duties.

Ensure Competency & Training – Only certified operators and trained riggers should be assigned to lifting duties.

During the Lift

Use Tag Lines – Control load swing with at least two tag lines, especially in windy conditions.

Use Tag Lines – Control load swing with at least two tag lines, especially in windy conditions. Certified Signallers Only – Only the designated and trained rigger should communicate with the operator using standardized hand signals or radios.

Certified Signallers Only – Only the designated and trained rigger should communicate with the operator using standardized hand signals or radios. Maintain Exclusion Zones – Clearly mark and enforce restricted areas using barriers, tape, and spotters.

Maintain Exclusion Zones – Clearly mark and enforce restricted areas using barriers, tape, and spotters. Monitor Conditions Constantly – Stay alert to environmental or mechanical changes. If anything seems unsafe, stop the lift immediately.

Monitor Conditions Constantly – Stay alert to environmental or mechanical changes. If anything seems unsafe, stop the lift immediately. Empower the Team – All team members should have the authority to halt operations if Safety is compromised.

Empower the Team – All team members should have the authority to halt operations if Safety is compromised.

Personal Safety

PPE for All Crew – Mandatory: hard hats, high-visibility vests, gloves, safety boots, and harnesses when working at height.

PPE for All Crew – Mandatory: hard hats, high-visibility vests, gloves, safety boots, and harnesses when working at height. Rigger-Specific Gear – Riggers must wear leather gloves and reflective jackets.

Rigger-Specific Gear – Riggers must wear leather gloves and reflective jackets. Sling Checks Before Use – Always inspect and test lifting slings, hooks, and shackles.

Sling Checks Before Use – Always inspect and test lifting slings, hooks, and shackles. Watch for Crush Zones – Avoid pinch points and stay clear of load paths.

Watch for Crush Zones – Avoid pinch points and stay clear of load paths.

After the Lift

Document Post-Lift Checks – Record inspection results, note weather conditions, and any observations during the lift.

Document Post-Lift Checks – Record inspection results, note weather conditions, and any observations during the lift. Secure and Store Equipment – Retract booms, stow tag lines, and store slings, chains, and tools properly.

Secure and Store Equipment – Retract booms, stow tag lines, and store slings, chains, and tools properly. Conduct a Team Debrief – Discuss what went well, identify near-misses or concerns, and update your lift plan or training records accordingly.

Conduct a Team Debrief – Discuss what went well, identify near-misses or concerns, and update your lift plan or training records accordingly.

From my own experience: One Real Incident

“During a plant audit last year, we noticed that the team used a mobile crane without ground mats on wet soil. Within 15 minutes of operation, the crane began to tilt. Thankfully, no one was hurt—but that lift was seconds from becoming a fatal one. All it took was a missed checklist item. That’s why we preach prevention every single day.”

This near-miss wasn’t just about bad ground conditions—it highlighted a serious gap in training, risk awareness, and compliance with procedures. No matter how big or small the lift, Safety depends on a trained team that follows every step, every time.

Recommended Safety Training Based on Real Risks

Lifting Operation Safety Training

Lifting Operation Safety Training Competent Rigger Training

Competent Rigger Training Forklift Safety Training

Forklift Safety Training Defensive Driving Training

Defensive Driving Training

To Explore our more safety courses: Click here

-Mr. Varun Vignesh, HSE Expert, Safety Consultant, Green World Group

Our Lifting Safety Courses