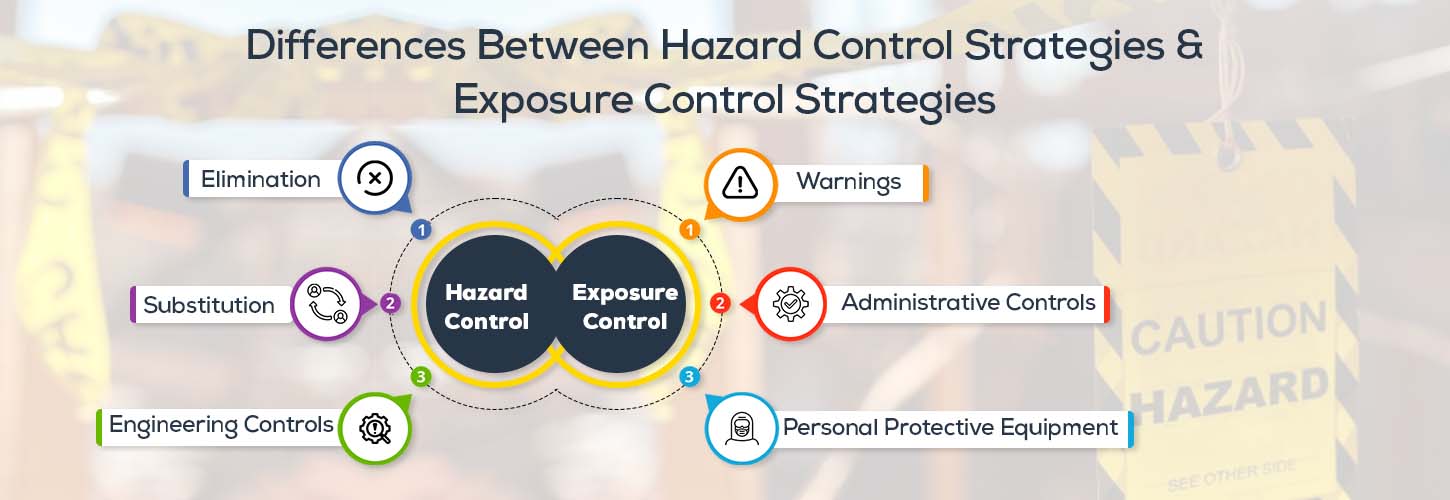

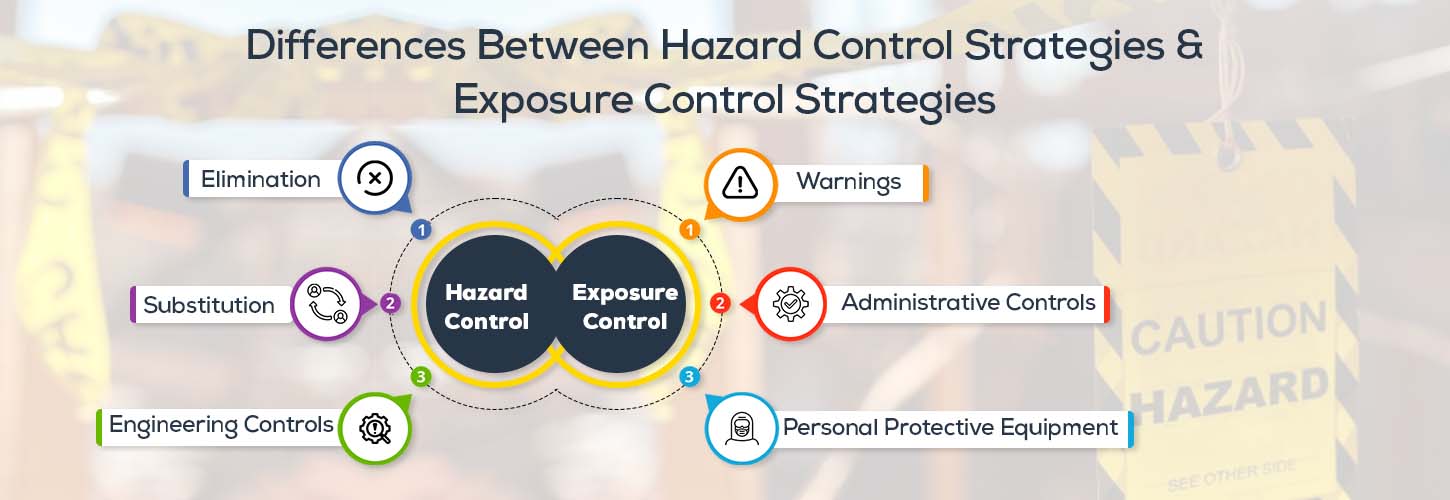

Differences Between Hazard Control Strategies & Exposure Control Strategies

Differences Between Hazard Control Strategies & Exposure Control Strategies

Safety team professionals identify every major control strategy that would mitigate the health hazards and exposure of employees to such hazards. We can categorize these fundamental strategies into a “Hierarchy of Controls.” Whenever there are suggestions related to the implementation of corrective actions and bringing improvements in the system, Occupational Health and Safety Management Systems highly recommend that employers adopt a hierarchy of hazard controls.

Hazard Control Strategies

Of the below strategies listed, the first three strategies are intended to control hazards and the strategies at the bottom have their best in changing the exposure to hazards. Since controlling hazards always have their priority over controlling behavior, these strategies have their top position in the hierarchy.

-

Elimination – eliminating the hazard is the best hazard control. Eliminates the hazard altogether from the workplace.

-

Substitution – lessens the hazard. This strategy involves replacing the hazard with something that is less hazardous. This approach is more relevant to scenarios where it is not feasible to eliminate the hazard.

-

Engineering controls – reduce the hazards at its source – design. This strategy keeps people isolated from hazards by designing or redesigning equipment, tools, machinery, and facilities. E.g.: including work processes or local ventilation systems installation to remove vapors at their source.

Exposure Control Strategies

When hazard controls are not sufficient, these strategies make an effort in regulating employee behaviors to reduce or eliminate exposure to existing hazards. Since we deal with human behavior, it is obviously more challenging to control human behaviors than hazards.

-

Warnings – awareness is increased through signs, alarms, labels, signals, placards, cones, and other warning methods. Eg: A warning sign can alert an employee entering a confined space.

-

Administrative/work practice controls – reduces or eliminates the exposure to hazards. This strategy reduces the hazards by changing the way the workers do their jobs by implementing training, processes, procedures, practices, policies, and safety rules. This strategy addresses root causes and thus strengthens the weaknesses in the systems.

-

Personal Protective Equipment (PPE) – exposure is reduced/eliminated through personal barriers. Typically, this method is used along with other hazard reduction approaches. When the first three approaches of hazard control strategies are not feasible, relevant PPE such as gloves, safety goggles, safety shoes, helmets, and protective wear is useful. PPE must be carefully chosen, ensured for fitness, regularly refitted, properly worn, maintained well, and replaced when needed.