MSHA Part 46 Surface Mining Refresher Overview

The course is devised to meet the provisions mentioned in the Annual Refresher Training 30 CFR §46.8. Employees get this routine annual training which intended to update them with new and existing hazards, risks and dangers, healthy practices, regulations, preventive measures and safe usage of mine equipments. This course meets two hours of the mandatory eight hour annual refresher training needs. You can select additional courses from our list of Surface Mining training which will help workers to undergo the remaining required hours.

Governing regulations

Title 30 CFR § 46.8 requires 8 hours of annual refresher training which should be held for miner who completes 12 months in the job or not more than 12 months after the completion of previous annual training period. The training must incorporate new challenges and risks which could affect health or safety of miners.

Every on-site surface mine worker must undergo this training and also those who are visiting the mines and willing to undergo the safety training.

Every worker who is posted at mine sites must know the safety rules and regulations and is responsible for his and others’ safety. Hence from the management to the general workers, everyone has the responsibility towards ensuring safety and health of each other. While employer should ensure that everyone is properly informed and safety rules are strictly supervised, supervisors have the duty of providing training to subordinates and ensure that they are MSHA and OSHA complaints. Workers have to simply adhere to the safety guidelines and follow all the safe practices.

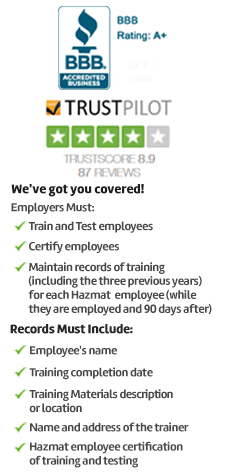

Employers want to make the workplaces MSHA compliant must have an approved training program conducted by an accredited trainer. Companies can have this or any of our safety courses as part of their safety training.

If you are willing to write an approved training plan, we can help you with our Part 46 Surface Mining Training Plan, the only such course available in the mining industry.

Course Overview

Annual Refresher course is made as per the training requirements of 30 CFR § 46.8 for the welfare of the miners. The training is focused on various health and safety issues, existing hazards, precautions, preventive measures, protective gears, safe operation of equipments and how to make the workplaces MSHA and OSHA compliant.

Learners get to know the impacts of environmental hazards, chemical hazards, equipment hazards and physical hazards prevalent at surface mines and surrounding areas. The training covers the nuances of best practices to prevent accidents and losses. Learners also know how to use various equipments at surface mines safely.

Who Must Take this Course?

This annual refresher course has been designed for individual mine operators, managers, supervisors, safety experts, mechanics, drivers and all other general workers at surface mines who are required to be MSHA compliant.

Course Format

Our MSHA Part 46 Surface Mining Refresher Overview training course has been designed with accredited content with easy to understand graphics and audio presentations and hordes of questions for better preparation for the final exam.

Candidates completing the course successfully are provided with the hardcopy of the completion certificate along with a printable wallet card.

Continuing education credits?

Students will receive 0.2 CEUs (or 2 CMEs) for completing this safety training.

Topics Covered

- About This Course

- Course Objectives

- Introduction to the MSHA Part 46 Annual Refresher Training Course

- Training Records

- General Causes of Mining Accidents

- Overview of Surface Mining Hazards

- Applicability

- Key Terms

- Chemical Hazards

- Class 1-Explosives

- Class 2-Gases

- Class 3-Flammable and Combustible Liquids

- Class 4-Flammable Solids

- Class 5-Oxidizers and Organic Peroxide

- Class 6-Toxic Materials and Infectious Substances

- Class 7-Radioactive Material

- Class 8-Corrosive Materials

- Class 9-Miscellaneous Hazardous Materials

- Environmental Hazards

- Highwalls

- Water Hazards, Pits, and Spoil Banks

- Illumination and Night Work

- Ground Conditions and Control

- Transportation Controls and Communication Systems

- Physical Hazards

- Electricity

- Explosives

- Noise

- Vibration

- Respiratory Contaminants

- Emergency Procedures

- Accident Prevention

- Protective Equipment

- Escape and Emergency Evacuation Plans

- Firewarning

- Firefighting

- First Aid

- Sanitation

- Equipment Hazards

- Mobile Equipment

- Conveyor Systems

- Crushers

- Cranes

- Dredgers

- Excavators

- Safety Best Practices

- Tool Use, Maintenance, and Repair

- Material Handling

- Fall Prevention and Protection

- Moving Objects

- Machine Guarding

- Miners’ Rights

- Summary

- Additional Resources

- Exam

NEBOSH CERTIFICATE

NEBOSH CERTIFICATE NEBOSH DIPLOMA

NEBOSH DIPLOMA IOSH

IOSH SAFETY DIPLOMA

SAFETY DIPLOMA CPD UK

CPD UK ROSPA UK

ROSPA UK FOOD SAFETY

FOOD SAFETY