Introduction

The oil and gas industry is often described as “high-risk, high-reward” — consistently ranks among the most dangerous sectors for worker safety. Unlike other industries, risks here are inherent, constant, and magnified by the scale of operations.

This blog explores why the oil and gas sector is considered a high-risk industry, identifies the 10 most common hazards, and their control measures with process safety management principles.

Why Is Oil and Gas a High-Risk Industry

Every stage of the oil and gas lifecycle—from offshore drilling and subsea pipelines to refining and product distribution—carries inherent dangers. Workers are exposed to toxic substances, high-pressure systems, and volatile environments where a minor error can escalate into a major accident.

Offshore platforms operate in harsh marine conditions, far from land and emergency response, while refineries handle hundreds of thousands of barrels daily, where even a single equipment failure can trigger fire, explosion, or toxic release, causing serious injuries to workers and large-scale operational shutdowns.

The common hazards include,

Chemical Hazards: Exposure to hydrogen sulphide (H₂S) during drilling, benzene in refining, and harmful vapours in storage areas.

Physical Hazards: Risks from high-pressure equipment, rotating machinery, and confined spaces.

Biological Hazards: Contact with microorganisms in offshore and wastewater systems.

Environmental Hazards: Natural threats such as cyclones, seismic activity, and extreme heat affect operations.

Environmental hazards are particularly complex—an unexpected storm or seismic shift can disrupt multiple systems simultaneously, turning a local issue into a large-scale emergency.

Real Oil and Gas Accident Statistics: Importance of Process Safety Management Training

Between 2014 and 2017, India’s petroleum sector reported 309 accidents, resulting in 81 deaths and 193 injuries (Standing Committee on Petroleum & Natural Gas, PRS India).

A (Comptroller and Auditor General) CAG audit ( 2014–2019) revealed that Indian Oil Corporation Limited (IOCL): 113 major and 97 minor accidents during fuel transport. The audit also noted that 22% of India’s oil and gas pipelines have exceeded their 25-year design life, increasing the risk of leaks and ruptures.

The above statistics highlight that the human and organisational factors contribute to over 70% of oil and gas accidents in India, primarily due to errors in judgment, procedural lapses, inadequate training, and mishandling of equipment, insufficient safety audits and poor monitoring emphasize the importance of safety training and strict adherence to process safety management procedures.

10 Most Common Risks in Oil & Gas industries and Their Control Measures

| Oil & Gas Hazard | Risk | Control Measures |

|---|---|---|

| Fire and Explosion | Hydrocarbon leaks/gas releases can ignite, causing fires or explosions | Gas detection, hot work permits, electrical classification, emergency readiness |

| Toxic Gas Exposure | H₂S/CO exposure >100 ppm can cause respiratory failure or death | Continuous gas monitoring, PPE, safety drills, rapid evacuation procedures |

| Blowouts | Uncontrolled release of oil/gas during drilling can cause fires, explosions, and environmental damage | Blowout preventers, well control procedures, trained crews |

| Confined Space Hazards | Oxygen-deficient/toxic atmosphere in tanks/vessels cause suffocation | Permit-to-work systems, atmospheric testing, ventilation, emergency rescue arrangements |

| Chemical Burns & Exposure | Contact with acids/caustics causes burns or chronic health effects | Use MSDS (Material Safety Data Sheets), provide PPE, emergency showers and eyewash stations |

| Mechanical Failures | Pressure vessels, valves, and rotating machinery failures can cause catastrophic incidents, including explosions or entrapment | Regular inspections, preventive maintenance, pressure relief devices, adherence to SOPs |

| Transportation Risks | Transporting oil and gas through pipelines, tankers, or remote road networks poses high risks of collisions, spills, or fires | Journey planning, vehicle maintenance, driver training, transport monitoring |

| Falls from Height | Offshore/refinery work leads to severe fall-related injuries | Fall arrest systems, guardrails, inspections, working-at-height training |

| Electrical Hazards | Electrical Faults in hazardous zones cause shocks, burns, or explosions | Certified equipment, hazardous area classification, competent personnel |

| Environmental Releases | Spills, leaks, or emissions can harm ecosystems, communities, and company reputation | Containment systems, spill response plans, continuous environmental monitoring |

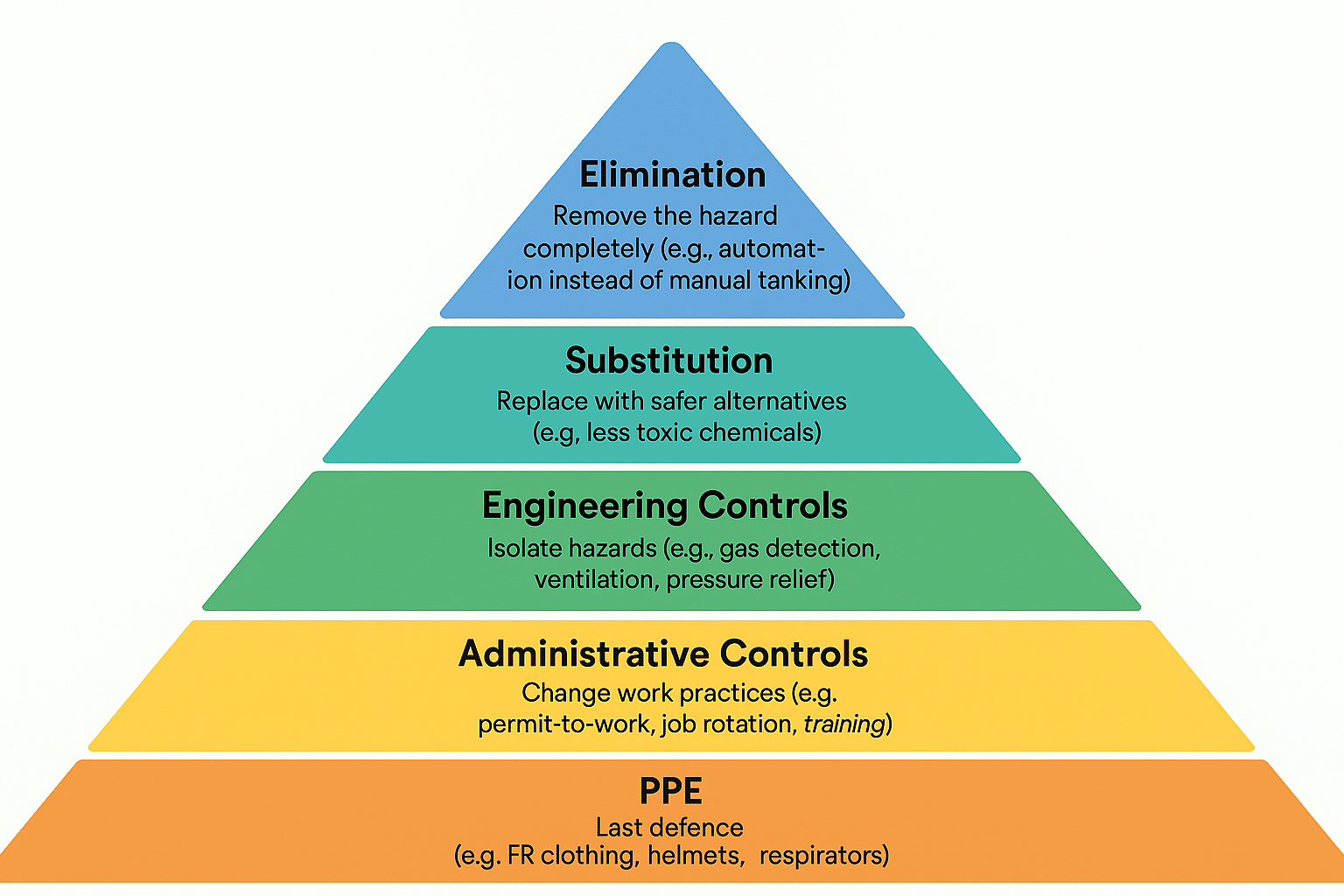

Hierarchy of Hazard Controls in Oil & Gas Safety

Regulatory Frameworks Governing Safety

The oil and gas industry operates under a web of regulatory requirements, which differ across regions but share one common goal: keeping risks as low as reasonably practicable (ALARP).

United Kingdom: The Health and Safety at Work etc. Act 1974, COSHH Regulations, DSEAR, and the Offshore Installations (Safety Case) Regulations 2005 form the foundation of oil and gas safety.

United Kingdom: The Health and Safety at Work etc. Act 1974, COSHH Regulations, DSEAR, and the Offshore Installations (Safety Case) Regulations 2005 form the foundation of oil and gas safety. United States: OSHA standards and American Petroleum Institute (API) guidelines drive safety compliance.

United States: OSHA standards and American Petroleum Institute (API) guidelines drive safety compliance.

India follows the Oil Industry Safety Directorate (OISD) standards under the Ministry of Petroleum & Natural Gas. While over 121 safety standards exist—21 mandated under Petroleum Rules—implementation and enforcement often lag global norms.

High-profile incidents such as the 2020 Assam gas well blowout, which displaced over 11,000 people, highlight ongoing gaps. This event makes skilled safety professionals in process safety and oil & gas vital for India to match global best practices.

Which Course Is Perfect for Oil and Gas Safety?

Working in oil and gas isn’t like a typical workplace—there are significant accident hazards that need careful management. The NEBOSH Process Safety Management Certificate(PSM) is designed specifically for professionals in this industry. It teaches practical skills such as

Process hazard analysis and risk assessment techniques

Process hazard analysis and risk assessment techniques Management of change (MoC) procedures

Management of change (MoC) procedures Incident investigation and root cause analysis

Incident investigation and root cause analysis Emergency response planning

Emergency response planning

This qualification strengthens a professional’s ability to shape safety culture and maintain compliance with international standards.

Final Thought

The oil and gas industry will always carry inherent risks, but with the right knowledge, systems, and training, these risks can be controlled to protect both people and operations.

For professionals committed to advancing their careers in this field and looking to develop strong process safety skills through specialised training like NEBOSH Process Safety Management, contact Green Word– Your Accredited NEBOSH Gold Learning Partner.

-Mr. Varun Vignesh, HSE Expert, Green World Group