Unsafe Act and Unsafe Condition – As HSE Expert My view

“Accidents don’t just happen — they are caused.”

Every workplace incident can be traced to either an unsafe act or an unsafe condition. When people ignore safety rules or when the work environment itself is hazardous, the result is the same — injuries, downtime, and loss.

The good news?

Both can be identified, controlled, and prevented before leading to incidents, near misses, and injuries.

Even though technology has automated several critical and hazardous functions previously carried out by workers, research shows that about 88% of accidents are caused by unsafe acts by employees, while 10% result from unsafe conditions in the workplace. Only a tiny 2% occur due to factors beyond human control.

So, if you are a serious learner and looking for details and guidance on “Unsafe Act and unsafe conditions “this post is for you!

Whether you’re a safety manager, business owner, or employee, this comprehensive guide will help you identify, prevent, and address these workplace hazards effectively.

What is Unsafe Act and Unsafe Condition in the Workplace?

The simple definition of Unsafe Act and Unsafe Condition is:

Unsafe Act – People Creating Risk

An unsafe act is a risky behavior carried out by a person that increases the likelihood of accidents, injuries, or damage. It occurs when someone behaves, reacts, or performs a task in an unsafe manner by not following required safety procedures or protocols.

Unsafe Condition- Place or environment creating risk

An unsafe condition is a hazard in the workplace environment that can cause injury or an accident.It happens because of the surroundings, not someone’s behavior.

In general, unsafe activities can lead to unsafe conditions. Any condition or situation (electrical, chemical, biological, physical, mechanical and environmental) that increases the risks and dangers of accidents can be called unsafe conditions.

Difference Between Unsafe Act and Condition

| Aspect | Unsafe Act | Unsafe Condition |

|---|---|---|

| Cause | Human behaviour — carelessness, lack of awareness, rushing, or ignoring rules | Environment, equipment, or system failures — poor maintenance, faulty tools, or unsafe setups |

| Created By | Worker actions | Workplace or system issues |

| Impact | Immediate risk to self and others | Hidden or long-term risk that can trigger accidents |

| Example | Using damaged tools, bypassing safety guards, or ignoring PPE | Slippery floors, exposed wires, broken machinery, poor lighting |

| Prevention | Training, supervision, safety culture, behaviour-based safety | Inspections, maintenance, engineering controls, hazard correction |

5 Common Examples of Unsafe Act and Unsafe Condition with Pictures

Unsafe Act Examples

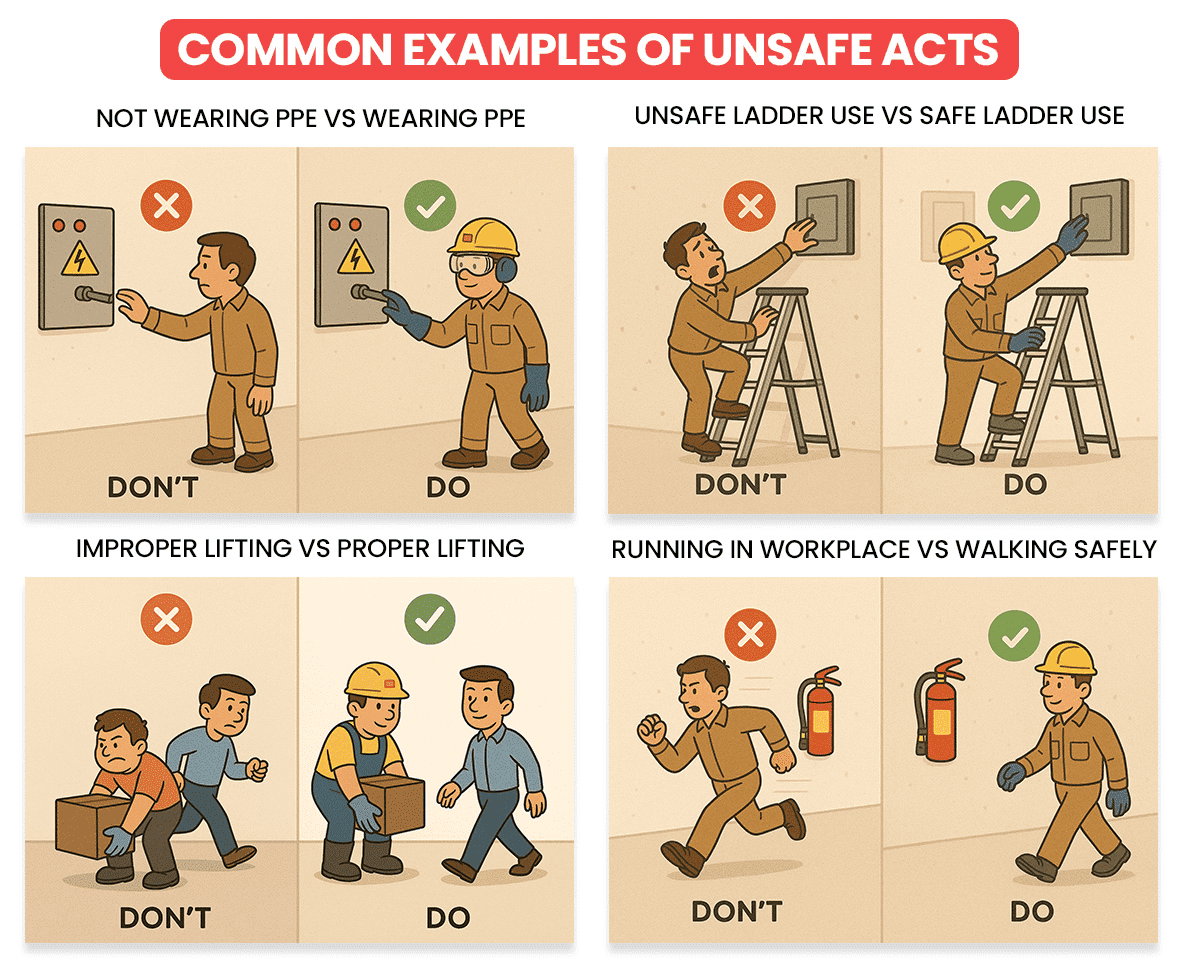

1.Ignoring Safety Gears (PPE): The Very First warning

Failing to wear personal protective equipment (PPE) such as helmets, gloves, goggles, or safety shoes. Workers may skip PPE to save time or due to overconfidence, but this significantly increases the risk of injuries from falling objects, sharp tools, or chemical splashes.

2. Misuse of Equipment and Machinery

Operating machinery without proper training or approval, using faulty tools, removing safety guards, skipping maintenance checks, or ignoring Lockout/Tagout (LOTO) procedures can quickly result in severe injuries or fatalities — even for experienced workers.

3. Improper Lifting Techniques

Lifting heavy objects incorrectly, twisting while carrying a load, or attempting to lift alone when a team lift is needed can cause back injuries and strains. Unsafe lifting often occurs when workers are in a hurry or underestimate the weight of the object.

4. Distracted Behaviour

Engaging in horseplay, running, joking, or using mobile phones in hazardous areas like confined spaces, working at heights, near machinery, or slippery floors can easily lead to accidents. Distractions reduce awareness of surroundings, increasing the risk of slips, trips, falls, or collisions.

5.Communication and Reporting Failures

Failing to report near-misses or potential hazards, ignoring safety warnings from coworkers, not communicating safety concerns to supervisors, or providing inadequate safety briefings before high-risk tasks can significantly increase the risk of workplace accidents and injuries.

Unsafe conditions Example

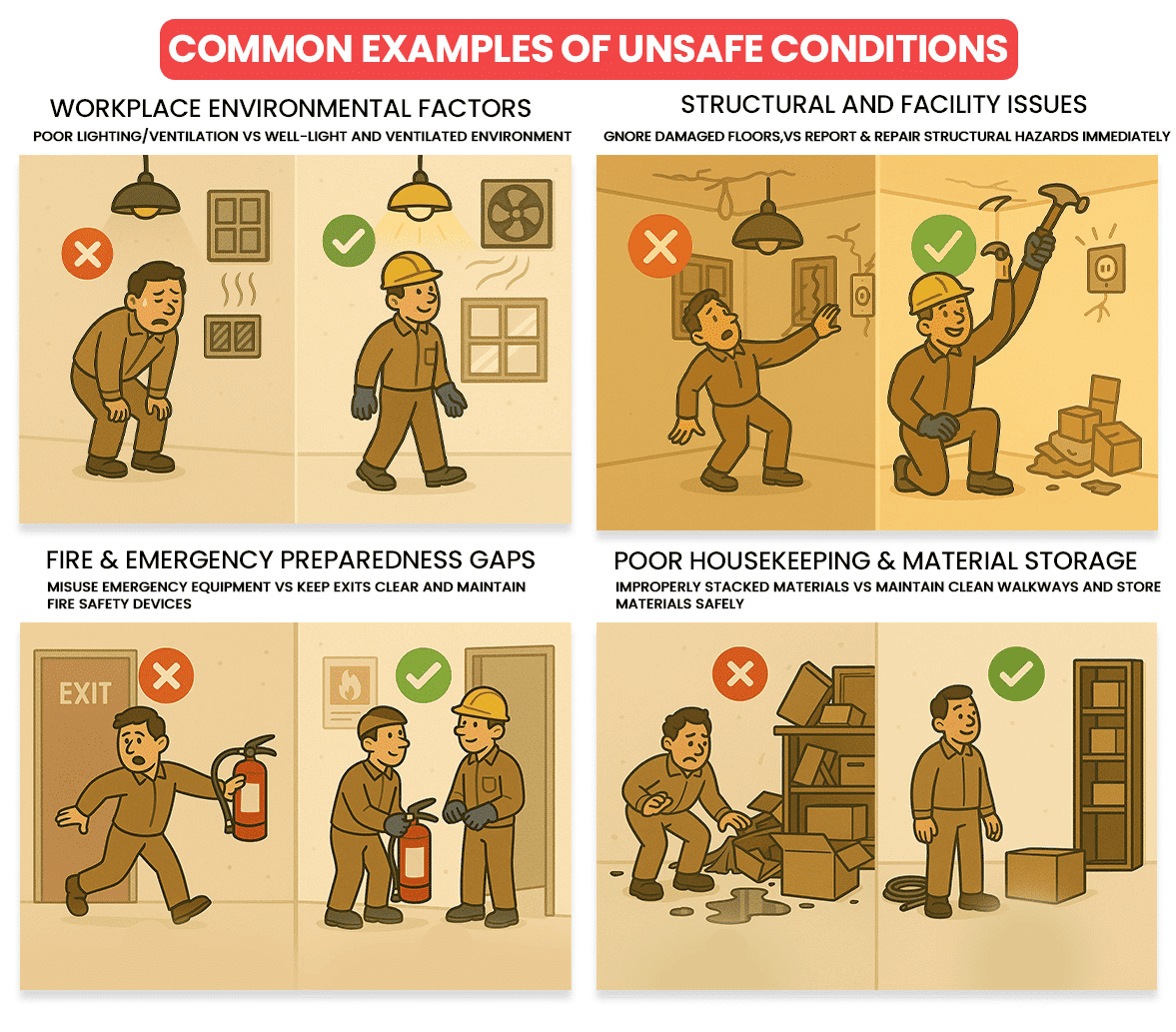

1.Workplace Environmental Factors

Overcrowded workspaces, poor lighting in office setups, excessive noise from machineries, and extreme indoor temperatures can make the workplace unsafe. It can cause slips, trips, falls, stress, hearing loss, or heat/cold-related illnesses.

2.Structural and Facility Issues

Damaged flooring with holes, cracks, or uneven surfaces, faulty electrical wiring or exposed components, broken or missing guardrails on elevated platforms, and leaking roofs create serious risks of falls, electrocution, and injuries.

3.Fire and Emergency Preparedness Gaps

Blocked exits, inaccessible fire extinguishers, malfunctioning alarms, and the absence of regular fire drills can delay emergency response and increase the risk of injury or property damage during a fire.

4.Poor Housekeeping and Material Storage

Disorganized work areas, unsafe stacking of materials, chemical or oil spills, and blocked access to emergency tools or exits create serious risks of injuries, fires, and operational delays.

5.Lack of Safety Awareness and Training

Employees without proper safety knowledge, unfamiliar with hazard signs, or not trained in emergency procedures are more likely to make errors, increasing the chances of workplace incidents.

What is Near Miss in Unsafe Act and Condition Safety?

A near miss is an unplanned event that did not result in injury, illness, or damage, but had the potential to cause harm.

Research shows that for every 300+ unsafe acts or conditions; there can be approximately: 3,000 near misses – (incidents where no injury occurred but had the potential to cause harm), 300 minor injuries, 30 major injuries and 1 fatality

This statistic demonstrates that near misses are direct warnings of unsafe acts and unsafe conditions Reporting and analysing near misses allows organizations to correct unsafe behaviours and hazardous conditions before they result in injury, making near-miss management a key part of accident prevention strategies.

How to Prevent Unsafe Act and Unsafe Condition Hazards in workplace

Unsafe Acts:

Encourage employees to report hazards and near misses immediately to prevent potential accidents.

Encourage employees to report hazards and near misses immediately to prevent potential accidents. Conduct regular, role-specific safety training and toolbox talks to reinforce safe work practices.

Conduct regular, role-specific safety training and toolbox talks to reinforce safe work practices. Pre-plan tasks by identifying potential risks and applying suitable control measures before starting work.

Pre-plan tasks by identifying potential risks and applying suitable control measures before starting work. Ensure employees consistently wear the correct PPE required for each task.

Ensure employees consistently wear the correct PPE required for each task. Continuously monitor work activities and immediately address unsafe behaviours, while acknowledging and encouraging safe practices to build strong safety habits.

Continuously monitor work activities and immediately address unsafe behaviours, while acknowledging and encouraging safe practices to build strong safety habits. Strictly follow all established safety procedures and instructions from supervisors to ensure compliance with organizational safety rules.

Strictly follow all established safety procedures and instructions from supervisors to ensure compliance with organizational safety rules.

Unsafe Conditions:

Maintain clean, organized, and clutter-free work areas to reduce slips, trips, falls, and fire risks.

Maintain clean, organized, and clutter-free work areas to reduce slips, trips, falls, and fire risks. Carry out scheduled workplace inspections and audits to detect and eliminate hazards early.

Carry out scheduled workplace inspections and audits to detect and eliminate hazards early. Monitor environmental factors such as lighting, noise, temperature, and ventilation to keep conditions safe.

Monitor environmental factors such as lighting, noise, temperature, and ventilation to keep conditions safe. Implement preventive maintenance for equipment and machinery to avoid breakdowns and safety failures.

Implement preventive maintenance for equipment and machinery to avoid breakdowns and safety failures. Apply engineering controls and design improvements wherever possible to reduce exposure to hazards.

Apply engineering controls and design improvements wherever possible to reduce exposure to hazards. Display clear safety procedures, warning signs, and SOPs at accessible and visible points.

Display clear safety procedures, warning signs, and SOPs at accessible and visible points. Manage shift schedules, provide adequate breaks, and avoid overcrowding to reduce fatigue and maintain alertness.

Manage shift schedules, provide adequate breaks, and avoid overcrowding to reduce fatigue and maintain alertness.

Safety is not only the organization’s responsibility; every employee is responsible for their own safety, the safety of colleagues, and the workplace. The organization can implement rules like employees who fail to follow safety procedures may face fines or penalties. To encourage safe behaviour and accident reporting, the organization rewards employees who consistently follow safety practices and can appoint a safety leader among workers to oversee compliance and promote a positive safety culture.

Final Note

Prevention is always better than cure. A proactive safety culture—where employees are aware, trained, and motivated to follow safety procedures—ensures not only compliance but also the well-being of every individual on site. Remember: every action counts, every hazard matters, and every employee plays a vital role in creating a safer workplace.

Join Hands with Green World today,

Train your team, conduct safety audits, and build a safer workplace—together!

-Mr. Varun Vignesh, HSE Expert, Green World Group