Tool Box Talks – Manual Material Handling

Manual Material Handling

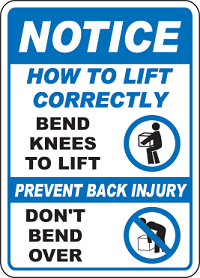

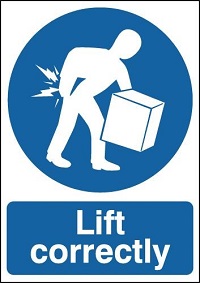

Safe lifting techniques:

It is necessary to use appropriate type gloves when handling rough, sharp, hot, slippery, odd shaped and hazardous materials. Safety boots or shoes should be worn to protect toes from falling loads. Prior to manual lifting / handling make sure loads are easy to lift. It is best to know the weight of the load so that could be decided either the load is to be lifted manually or by mechanical equipments.

Safety Tips:

1. If possible avoid lifting materials manually.

2. Determine the weight of the load; this can be obtained by looking at labels from the coverings or packaging list. In other cases, if the weight of the load seems to be heavier one should select appropriate type mechanical lifting aid to lift it.

3. Feet should be at a comfort and suitable distance and parallel behind the object.

4. Keep the materials to be lifted below eye level

5. Tuck the chin into line up the neck and spine.

6. Tuck in the elbows for more power.

7. Adopt the sit down position with the back straight, but not vertical.

8. Use whole hand and palm to get adequate grip on the object to be lifted and never try to lift just by fingers.

9. Maintain the weight directly over the feet and use the legs to push up, not the back.

10. Make sure the walkway to be used to travel with the load is clean and free from obstacles so that can avoid tripping and slippery chances due to spillages and leakages of oil, grease, water and liquids.

11. If it seems difficult to lift a load alone, always seek assistance or use mechanical device.

12. Ensure proper coordination in case multiple employees are to be involved in lifting.

13. Plan the direction of travel by carrying the load in case multiple employees are involved.

14. Determine timing of lifting and use counting mode.

15. Avoid pinch point chances while stacking the load.

NEBOSH CERTIFICATE

NEBOSH CERTIFICATE NEBOSH DIPLOMA

NEBOSH DIPLOMA IOSH

IOSH SAFETY DIPLOMA

SAFETY DIPLOMA CPD UK

CPD UK ROSPA UK

ROSPA UK FOOD SAFETY

FOOD SAFETY