OSHA Electrical Safety Training Course

This OSHA electrical standards course helps students understand the electrical safety measures for medical and dental office workers and also for other employees and contractors who are exposed to hazardous work conditions dealing with energized parts, electrical equipments and live wires.

Employees who undergo this training course can protect them and others from the danger of electric shocks, electrocution, burn injuries, explosion or fire. Workers who are assigned responsibilities in places having electrical hazards must undergo this course and get certified before entering into the risk-prone zones.

Governing regulations

Our online occupational electrical safety course has been formulated to satisfy the training parameters as prescribed by OSHA’s 29 CFR § 1910.301 to 1910.399 Electrical Safety Standard.

Course Overview

The course trains students to gain awareness and skills to follow OSHA’s General Industry Electrical standards 29 CFR 1910 Subpart S (1910.301 to 1910.399) and provides safety to workers in medical and dental offices against various electrical hazards. The training also covers compliance procedures, critical safety standards, types of electrical hazards and also various hazard controls measures that can be used to provide safe and healthy environment for workers.

Who Must Take this Course?

According to OSHA 29 CFR 1910.332 training standard under Scope(a), employees, who are likely to face electrical hazards such as electric shock and also those who are involved in electrical installations following the requirements of §1910.303 through 1910.308.

Employees in occupations listed in Table S-4 may also face electrical risk and hence are suggested to be trained. TABLE S-4 lists typical occupational categories of employees who face higher than normal risks of electrical accidents.

Categories of workers who should do this course include: Electricians, Electrical and electronic engineers, Stationary engineers, Welders, Blue collar supervisors, Electrical and electronic technicians, Electrical and electronic equipment assemblers, Material handling equipment operators, Industrial machine operators, Painters, Riggers and roustabouts and Mechanics.

Employers should take a call on joining their workers to this course to increase safety awareness and reduce the risk of accidents due to electrical hazards.

Course Format

Our OSHA Electrical Safety Training course has been formulated with excellent self-explanatory content prepared by safety experts, graphical and audio presentations, self-test questions and case studies to do well in the final exam.

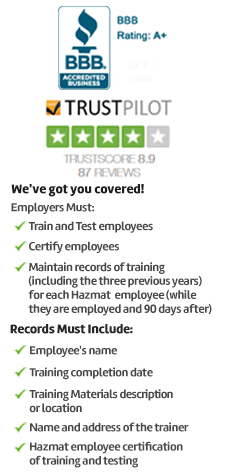

Every successful candidate at the end of the course will be provided with a hard copy of completion certificate along with a printable wallet card for their future studies.

Continuing education credits?

Each successful student will be eligible to receive 0.2 CEUs (or 2 CMEs) for completing this safety training.

Topics Covered

- Introduction to OSHA Electrical Standard Training

- Fatality and Injury Statistics

- Roles and Responsibilities

- Key Terms

- Design Safety Standards for Electrical Systems

- Examination of Equipment

- Installation of Equipment

- Electrical Connections

- Arcing Parts, Markings, and Disconnecting Devices

- Design Safety Standards for Equipment Operating at 600 Volts or Less

- Guarding of Live Parts, 600 Volts or Less

- Design Safety Standards for Equipment Operating at More Than 600 Volts

- Enclosures for Electrical Installations – More Than 600 Volts

- Indoor Installations – More Than 600 Volts

- Space Around Electrical Equipment, More Than 600 Volts

- Working Space, Entrances, and Illumination – More Than 600 Volts

- Wiring Design and Protection

- Branch Circuits and Receptacles

- Testing Equipment Grounding Conductors

- Outlet Devices and Receptacle Outlets

- Outside Conductors, 600 Volts or Less

- Clearances

- Services

- Overcurrent Protection

- Grounding

- Methods of Grounding Fixed Equipment

- Wiring Methods, Components, and Equipment for General Use

- Temporary Wiring

- Cabinets, Boxes, and Fittings

- Switches

- Conductors for General Wiring

- Fixture Wires

- Attachment Plugs and Appliances

- Motors, Motor Circuits, and Controllers

- Transformers and Capacitors

- Specialized Purpose Equipment, Locations, and Systems

- Hazardous Location Classification

- Classifications

- Electrical Installations

- Protection Techniques

- Safety-Related Work Practices

- Work Covered by The OSHA Electrical Standard

- Training

- Content of Training

- General Work Practices

- Work Practices Related to Exposed De-Energized Parts

- Re-Energizing Equipment

- Work Practices Related to Exposed Energized Parts

- Working On or Near Overhead Lines

- Illumination and Work in Confined or Enclosed Spaces

- Conductive Materials, Equipment, and Apparel

- Work Practices Related to the Use of Equipment

- Portable Electrical Equipment

- Electrical Power and Lighting Circuits

- Use of Protective Equipment

- Alerting Techniques

- Summary

- Additional Resources

- Exam

NEBOSH CERTIFICATE

NEBOSH CERTIFICATE NEBOSH DIPLOMA

NEBOSH DIPLOMA IOSH

IOSH SAFETY DIPLOMA

SAFETY DIPLOMA CPD UK

CPD UK ROSPA UK

ROSPA UK FOOD SAFETY

FOOD SAFETY