Introduction to Accident Investigation

Introduction to Accident Investigation

Every workplace accident offers valuable lessons for owners and safety managers. Even when every precaution is taken and all safety standards and policies are followed, an incident can still occur—and it’s then up to those responsible for a safe work environment to investigate its cause and close any gaps to prevent a recurrence.

Accident investigation goes beyond surface-level observation—it uncovers root causes, drives corrective actions, and promotes continuous improvement in workplace safety and regulatory compliance.

In this blog, I’ll share how a structured, expert-led accident investigation process can turn each incident into a catalyst for lasting workplace safety improvements, legal compliance, and peace of mind.

What is an Accident & Incident in Safety and Why Should It Be Investigated?

An accident is an unplanned event causing injury, damage, or loss. An incident includes accidents and near misses that could have caused harm. Investigating both helps prevent future risks and improve workplace safety.

Accident & Incident Investigation is a structured approach used to report, analyze, and identify the root causes of workplace incidents. Its purpose is to understand what happened, why it happened, and how to prevent similar incidents in the future by implementing practical corrective actions.

Under OSHA’s recordkeeping rule (29 CFR 1904), employers are required to investigate and document all workplace accidents. Here are additional reasons why conducting an incident investigation benefits your business and reduces future risks:

It uncovers the root cause of incidents, enabling you to develop effective action plans to prevent recurrence.

It uncovers the root cause of incidents, enabling you to develop effective action plans to prevent recurrence. It identifies gaps in your current risk control measures, helping you strengthen safety protocols.

It identifies gaps in your current risk control measures, helping you strengthen safety protocols. It reveals any previously unknown weaknesses in your health and safety compliance, allowing timely corrections.

It reveals any previously unknown weaknesses in your health and safety compliance, allowing timely corrections. For workers’ compensation and insurance claims, insurers may require detailed investigation findings.

For workers’ compensation and insurance claims, insurers may require detailed investigation findings. In legal cases, a thorough investigation demonstrates your proactive commitment to occupational safety, which can positively influence court outcomes.

In legal cases, a thorough investigation demonstrates your proactive commitment to occupational safety, which can positively influence court outcomes.

Moreover, investigating incidents and near misses reports highlights your dedication to workplace health and safety, boosting employee confidence and morale.

How Incidents Can Occur in the Workplace?

Direct Causes: Immediate hazards or unsafe actions

Direct Causes: Immediate hazards or unsafe actions Root Causes: Systemic failures in processes or training

Root Causes: Systemic failures in processes or training Human Factors: Errors or lapses due to fatigue, stress, or complacency

Human Factors: Errors or lapses due to fatigue, stress, or complacency Organizational Influences: Culture, leadership priorities, resource pressures

Organizational Influences: Culture, leadership priorities, resource pressures Environmental Conditions: Poor lighting, noise, layout, or housekeeping

Environmental Conditions: Poor lighting, noise, layout, or housekeeping Equipment Factors: Design flaws, missing safeguards, maintenance gaps

Equipment Factors: Design flaws, missing safeguards, maintenance gaps Procedural Gaps: Absent, unclear, or outdated safety procedures

Procedural Gaps: Absent, unclear, or outdated safety procedures External Influences: Contractor practices, supply-chain or regulatory changes

External Influences: Contractor practices, supply-chain or regulatory changes

Essential Steps to follow for an Effective Accident Investigation Process

The purpose of accident investigation is to uncover underlying factors that lead to accidents, enabling organisations to address weaknesses in systems, processes, or behaviours. Let see how to conduct a Step-by- step Incident investigation procedure to ensure workplace Safety are,

1.Secure the Scene & Gather Evidence

Immediately isolate and secure the site to prevent further harm and preserve evidence. Capture everything—photos, videos, notes—before anything is moved or changed.

2.Talk to Witnesses

Have conversations with those who saw or were involved in the incident. They often share details that cameras or reports miss.

3.Review the relevant Document.

Go through training records, maintenance logs, safety procedures, and past incident reports. These can reveal where things went wrong.

4.Conduct Root Cause Analysis

Look deeper to understand why the incident occurred. Use tools like the “5 Whys” to identify core issues—such as insufficient training, equipment malfunctions, or poor communication—that need to be addressed.

5.Develop and Recommend Control Measures

Once you’ve identified the root causes, suggest practical and achievable actions—like clearer instructions, better tools, or extra training—to stop the same accident from happening again.

6.Implement the Action Plan and Monitor Effectiveness

Turn your recommendations into a clear plan. Assign responsibilities, set deadlines, and keep checking to make sure the changes are actually making a difference.

Importance of Accident Investigation: Rising Workplace Accidents in India Demand Immediate Action

According to a 2024 report by IndustriALL Global Union, over 240 workplace accidents occurred across India’s manufacturing, mining, and energy sectors, resulting in more than 400 deaths and 850 serious injuries. These figures likely underrepresent the actual impact due to widespread underreporting, especially in high-risk industries such as chemical and pharmaceutical manufacturing.

A report by Deutsche Welle (DW) — Germany’s international public broadcaster — published in January 2024, revealed that on average, three workers die every day in Indian factories.

Additionally, government data indicated that 6,500 workers lost their lives over a five-year span across factories, ports, mines, and construction sites.

For more details about this article: The New Indian Express

My Perspective as a Safety Expert:

Underreporting remains a critical issue—many incidents go unreported due to fear of legal consequences, reputational risks, lack of awareness, or pressure to maintain production. In smaller businesses and informal sectors, the absence of a strong reporting culture only makes things worse.

To truly improve workplace safety, organizations must go beyond surface-level compliance. This means adopting accident reporting systems and implementing a structured accident investigation framework to identify root causes and take proactive steps to prevent accidents from recurring.

Equally important is making sure safety teams and supervisors are properly trained in how to investigate incidents. Without the right skills, critical risks go unnoticed. With them, every incident becomes a powerful opportunity to improve safety and prevent future harm.

Why Investing in Accident Investigation Training Matters

Beyond policies and procedures, effective accident investigation training plays a vital role in building safer workplaces.

When managers, supervisors, and safety officers are properly trained to investigate incidents, they can understand not just what went wrong but also why it happened in the first place.

This kind of training gives them hands-on skills to:

Carefully preserve and document all evidence to keep it accurate and reliable.

Carefully preserve and document all evidence to keep it accurate and reliable. Talk to witnesses openly and fairly, without jumping to conclusions.

Talk to witnesses openly and fairly, without jumping to conclusions. Use root cause analysis to truly understand what caused the incident, going beyond the obvious.

Use root cause analysis to truly understand what caused the incident, going beyond the obvious. Suggest clear and practical corrective actions that really make a difference.

Suggest clear and practical corrective actions that really make a difference. Ensure every step follows legal and regulatory requirements

Ensure every step follows legal and regulatory requirements

Conclusion

As an HSE expert, I truly believe that accident investigation is one of the most powerful tools we have to improve safety in the workplace. Every incident teaches us something important — helping us spot risks, strengthen our systems, and encourage accountability at all levels.

With workplace incidents rising and underreporting still common in India, it’s time for organizations to take a structured approach. Trained teams, thorough investigations, and root-cause analysis are key to preventing repeats and building a safer, more responsible work culture.

— Mr. Varun Vignesh, HSE Expert, Green World Group

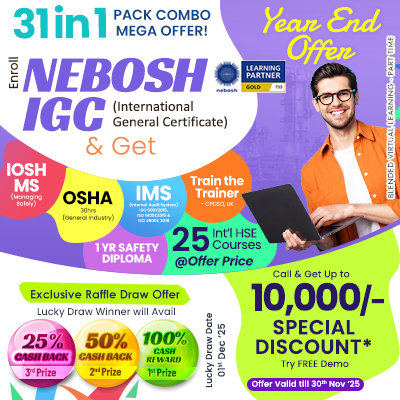

Looking for a certified HSE course like NEBOSH HSE Introduction to Incident Investigation or customised in-house training for your team? We offer flexible options—online or in person. Reach out to us today!

NEBOSH CERTIFICATE

NEBOSH CERTIFICATE NEBOSH DIPLOMA

NEBOSH DIPLOMA IOSH

IOSH SAFETY DIPLOMA

SAFETY DIPLOMA CPD UK

CPD UK FOOD SAFETY

FOOD SAFETY